Whether customers come to us from the very beginning or after they run into issues with their current plastic injection molder, they know they’re in some of the best hands in the industry with PMC.U.S. Plastic Injection Molder Specializing in Engineering Resins & Complex Molding Issues  How your part will be used is undoubtedly one of the most important considerations for plastic injection molding design. While this may seem straightforward, there may be some important questions you have missed as part of this identification process, such as:What function(s) will your part serve? Is it a single component or part of an assemblyWhat market(s) is your part intended for?What application(s) will it be used in?Who will be handling your end product?Will the part endure continual use or periodic?Properties The final common processing defect is improper melt temperature. When using the processing guides supplied by the materials manufacturer you will see a range of temperatures suggested. This process value is important to making sure that you are not destroying any of the chemistry involved in the making of the final part. The mold temperature is equally as valuable in the development of stress. Before you attempt to mold the first part, make sure the resin purges out the nozzle in an even-smooth-creamy-melt for the entire amount of resin that is destined to be injected into the mold. It’s no good to have a nice creamy melt stream halfway through the injection of the material stream and the last half look like corn-cobbs. This process is already off on a bad start. Smooth is best!What’s the Bottom Line? Education and Training:Is the new molding house educated on your company’s needs? Are they updated on the processing manuals supplied by the material manufacturer? Your molding company should be aware of the mechanical properties that were advertised and defined in?the literature provided by the material?manufacturer.?Your engineering department believed these mechanical properties to be important, therefore they should be known and implemented. They will ultimately result in the survival of your product in its finished environment.Does my new molder have the proper knowledge to process the resin of my choice? Do they know how to utilize the best molding practices? Are they aware of resin drying time, heat history, and molding temperatures, etc., etc.? Be sure your new molder is aware of your machine settings. This is crucial in determining a dependable and high quality outcome for your products.Does the prospective molder have an effective training program for the employees??Are the employees aware of expectations, processes, and deadlines? Communicate your needs with your potential partner.Does the new molding house know how to handle raw materials; specifically the materials that will develop new products???Knowledge of the materials is essential in the molding technique.

How your part will be used is undoubtedly one of the most important considerations for plastic injection molding design. While this may seem straightforward, there may be some important questions you have missed as part of this identification process, such as:What function(s) will your part serve? Is it a single component or part of an assemblyWhat market(s) is your part intended for?What application(s) will it be used in?Who will be handling your end product?Will the part endure continual use or periodic?Properties The final common processing defect is improper melt temperature. When using the processing guides supplied by the materials manufacturer you will see a range of temperatures suggested. This process value is important to making sure that you are not destroying any of the chemistry involved in the making of the final part. The mold temperature is equally as valuable in the development of stress. Before you attempt to mold the first part, make sure the resin purges out the nozzle in an even-smooth-creamy-melt for the entire amount of resin that is destined to be injected into the mold. It’s no good to have a nice creamy melt stream halfway through the injection of the material stream and the last half look like corn-cobbs. This process is already off on a bad start. Smooth is best!What’s the Bottom Line? Education and Training:Is the new molding house educated on your company’s needs? Are they updated on the processing manuals supplied by the material manufacturer? Your molding company should be aware of the mechanical properties that were advertised and defined in?the literature provided by the material?manufacturer.?Your engineering department believed these mechanical properties to be important, therefore they should be known and implemented. They will ultimately result in the survival of your product in its finished environment.Does my new molder have the proper knowledge to process the resin of my choice? Do they know how to utilize the best molding practices? Are they aware of resin drying time, heat history, and molding temperatures, etc., etc.? Be sure your new molder is aware of your machine settings. This is crucial in determining a dependable and high quality outcome for your products.Does the prospective molder have an effective training program for the employees??Are the employees aware of expectations, processes, and deadlines? Communicate your needs with your potential partner.Does the new molding house know how to handle raw materials; specifically the materials that will develop new products???Knowledge of the materials is essential in the molding technique.

Who Is Sig Sauer Metal Injection Molding Mim Plant

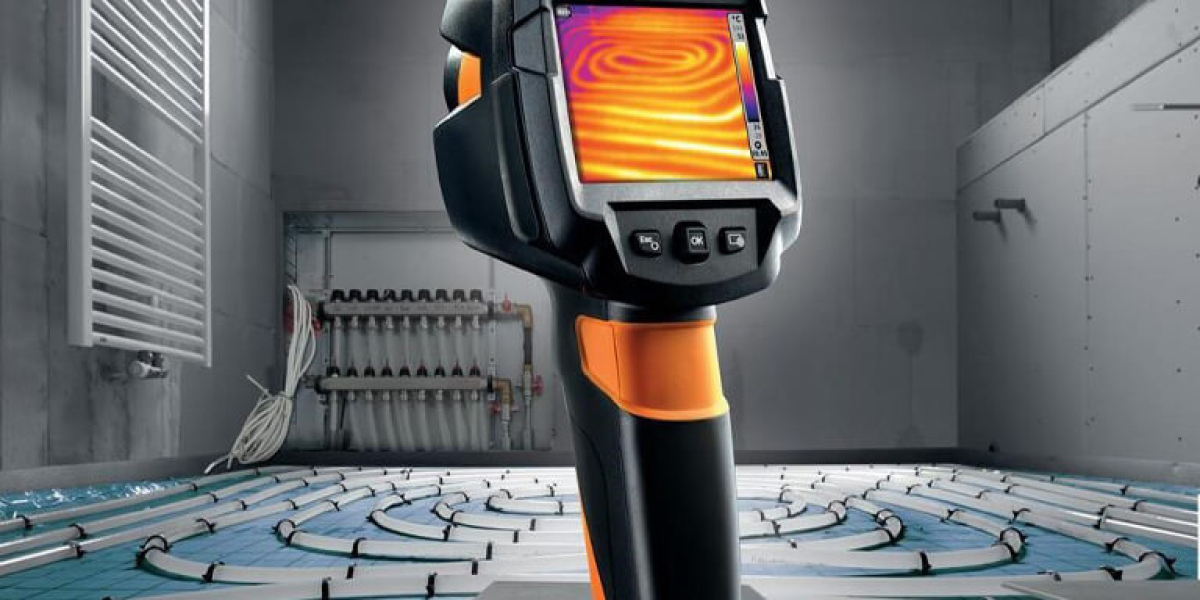

Engineering failure analysis through forensic insights is invaluable for uncovering hidden issues within plastic injection molded products. By conducting forensic research, laboratory analysis can uncover resin issues leading to product failure. In addition to material assessments, mold inspections, process monitoring, defect analysis, and historical data reviews help manufacturers identify the causes of product failures and prevent them from recurring. In the dynamic field of plastic injection molding, engineering failure analysis through forensic research plays a critical role in ensuring the success of projects across diverse industries. Residence time is the amount of time the resin is exposed to heat in the barrel. If there is inadequate residence time the molecules will not absorb heat uniformly throughout the material. The under-heated material will become stiff and will cool before the mold is properly packed. This causes the molecules to shrink at different rates during the cooling process which results in mold warpage. In plastic injection molding, gate design is critical to achieving molded part quality and productivity. Because gates are designed to allow melted plastic resins to move into the mold cavity, it’s imperative that gate material, size and location are optimized for structural, operational and aesthetic considerations.Material These markets (Electrical/Electronic, Appliance & Transportation) are each expected to grow by approximately 3-4% every year for the next 3 years, which will continue to propel the market demand for ABS resin in plastic injection molding.Electrical/Electronics In addition to providing plastic overmolding services, PMC provides a comprehensive range of other plastic molding services including mold design assistance, modeling, prototyping, manufacturing, and testing.

How To Make Injection Molds Pdf Free Download

PMC offers a comprehensive range of plastic molding services including mold design assistance, modeling, prototyping, manufacturing, and testing. PMMA is an economical material used for applications

requiring excellent optical, light, transmittance, and weatherability. Common products

include lighting and optical applications. PMMA is sometimes referred to as

acrylic glass as it is a lightweight, shatter-resistant alternative to glass. Advantages

include: Resistance to UV radiation and weatheringHigh refractive index and clarityGreat light transmissibility (white light

transmittance can be as high as 95%)Has the greatest surface hardness of any

plastic, making it scratch resistantDyes can be added to get a certain colorChemical resistance Today, there are only a few companies around the world who specialize in Engineering-Grade molding projects. Between the rarity of this specialty and the global freight distance, it can be a real challenge to find a capable domestic company to handle these projects. Please note, we make components for medical devices – not end-use medical products. For more information regarding FDA requirements, please click here. When it comes to plastic injection mold warpage, defects can be caused by several factors including:Inadequate Injection Pressure or TimeInadequate Residence TimeBarrel Temperature Too LowMold Temperature Too LowUneven Mold TemperaturesNozzle Temperature Too LowImproper Flow RateInconsistent Process CycleInadequate Gate SizeIncorrect Gate LocationLack of Ejection UniformityPart GeometryMold Burns