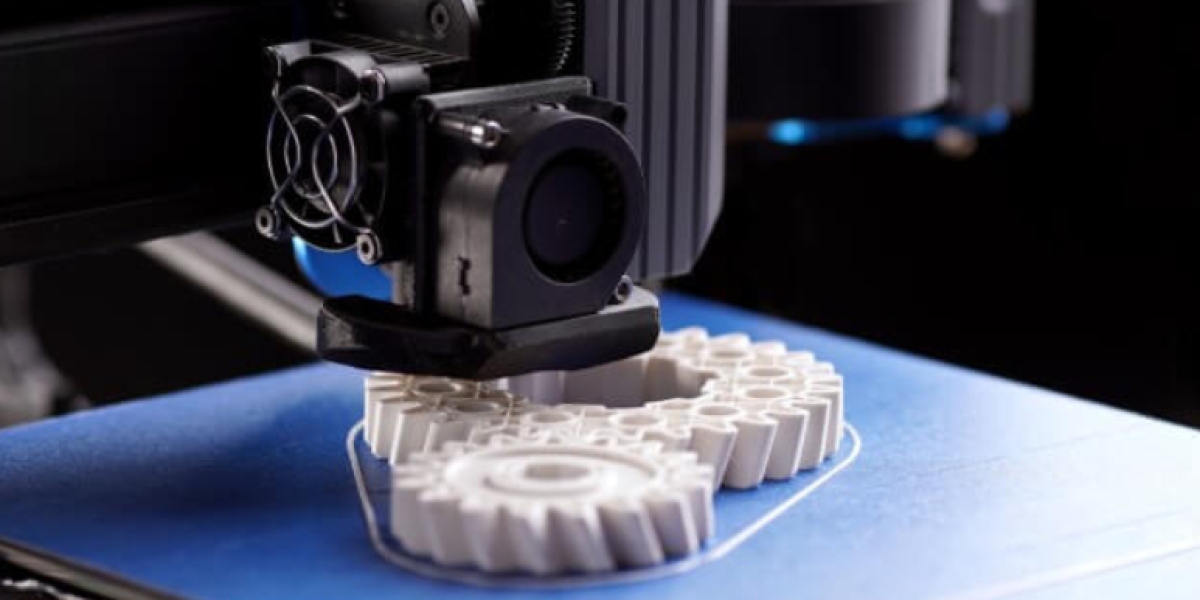

As this high-tech industry surges in demand, so too does the demand for ABS plastic injection molding.Appliances If materials are not compatible you may end up with component deformation or other overmolding failures. In plastic injection molding, cooling rate is the last section of the molding cycle. Plastic injection molding has brought about a manufacturing revolution, enabling the creation of intricate components with unparalleled efficiency. However, even this advanced technique is not immune to challenges, and issues may arise that lead to product failures. In such cases, conducting a comprehensive product failure analysis becomes crucial in order to get your product back on the market quickly with every chance the product will live up to a reasonable expectation of a long market presence.

How Does Injection Molding Machine With Abs Plastic Work

Part specifications you’ll want to detail in your plastic injection mold design include:Part SizePart GeometryWall ThicknessDimensional TolerancesNumber of CavitiesPresence of Sharp Corners or RibsPresence of Holes and CoresApplicable InsertsElectrical RequirementsApproximate Part Life ExpectancyOther Needed Secondary OptionsStrength Plastic Molded Concepts is a U.S based company that uniquely specializes in molding with engineered resins. We frequently provide plastic injection molding services for mission-critical parts in industries, such as aerospace/defense, automotive, medical and more. Pretty soon I was promoted up to a Material Handler. After that I was trained to be a person that sets the molds in the machines. Within a year I was starting the machines and training new operators! Whether it’s improper gate size or positioning, injection molding gate defects can become extremely expensive and time-consuming. In the PMC facility, Sawyer picks a part from the press and puts it on a computer numerical control (CNC) machine for holes to be drilled, detects when it is finished and places the part in a box. Sawyer waits until there are exactly 160 parts in the box, then pauses for an operator to come pick it up. The operator gives Sawyer a push to signal that it can continue, and the process repeats.

Are Mud Bases Used In Plastic Injection Molding In Mexico

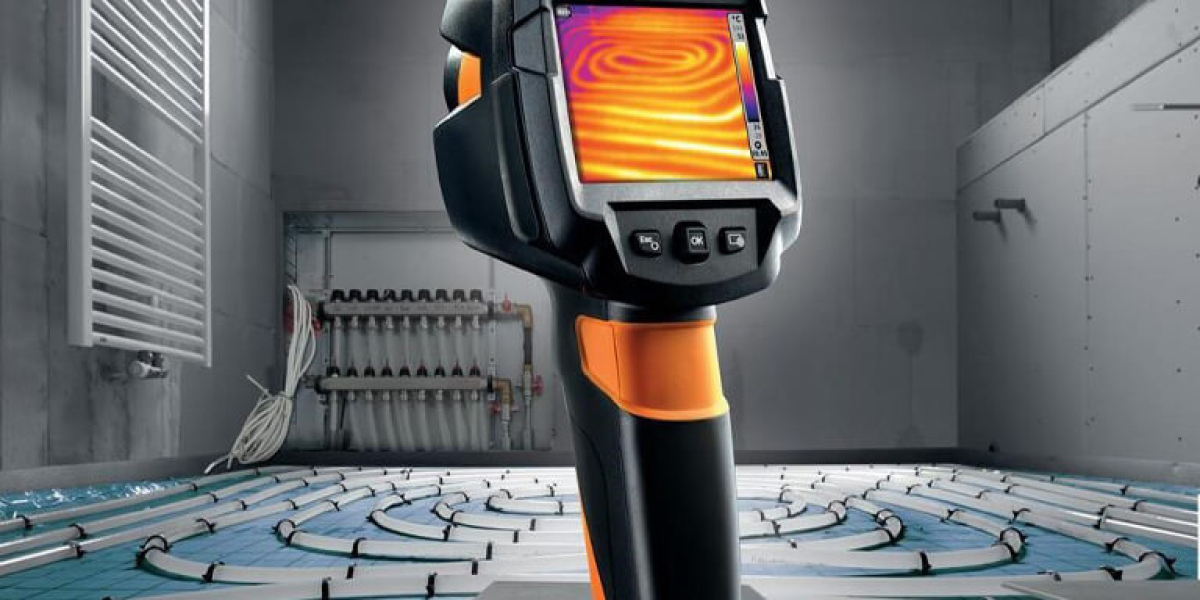

Operating environments is a key component in plastic injection mold design. Environmental factors that can affect your part may include:TemperatureMoistureChemicalsCorrosionUV RadiationMaterial CompatibilityFlame RetardationAesthetics Want to find out if your metal part can be successfully replaced by plastic?U.S. Plastic Molding Company Specializing in Engineered Resins Warpage in injection molding is a common challenge faced by manufacturers. Warpage refers to the distortion or deformation of a molded plastic part, often caused during its cooling process in the injection molding cycle. This can cause parts to fold, bend, twist, or bow, leading to potential complications in final product assembly. Injection molded plastic gears are now being used in electronic & electrical appliances, industrial equipment, the medical industry, the automotive industry & many more. The base layer is molded first and the additional plastic layer(s) are molded over and around the original part – resulting in a single, finished product.Overmolding Benefits:Strong Finished ProductLong Service LifeEnhanced SafetyMore Cost Efficient than Post-Molding FabricationOvermolding Product Examples:PCBRFIDPhonesPower Tools & Hand ToolsCar Steering Wheels*Special Notes