In the realm of quality control, visual inspection is a fundamental process that ensures products meet specified standards. This method involves examining items visually to identify defects or irregularities. But what exactly does visual inspection entail, and why is it crucial in various industries?

What is Visual Inspection?

Visual inspection is a non-destructive testing method that relies on the human eye or optical devices to assess the quality of products. It can be performed manually or with the aid of advanced technology, such as automated camera systems. The primary goal is to detect any flaws that could affect the functionality or safety of the product.

Techniques Used in Visual Inspection

There are several techniques employed in visual inspection, including:

- Manual Inspection: Trained inspectors visually examine products for defects.

- Automated Inspection: Machines equipped with cameras and sensors analyze products for quality assurance.

- Remote Inspection: Utilizing drones or other remote devices to inspect hard-to-reach areas.

Tools for Effective Visual Inspection

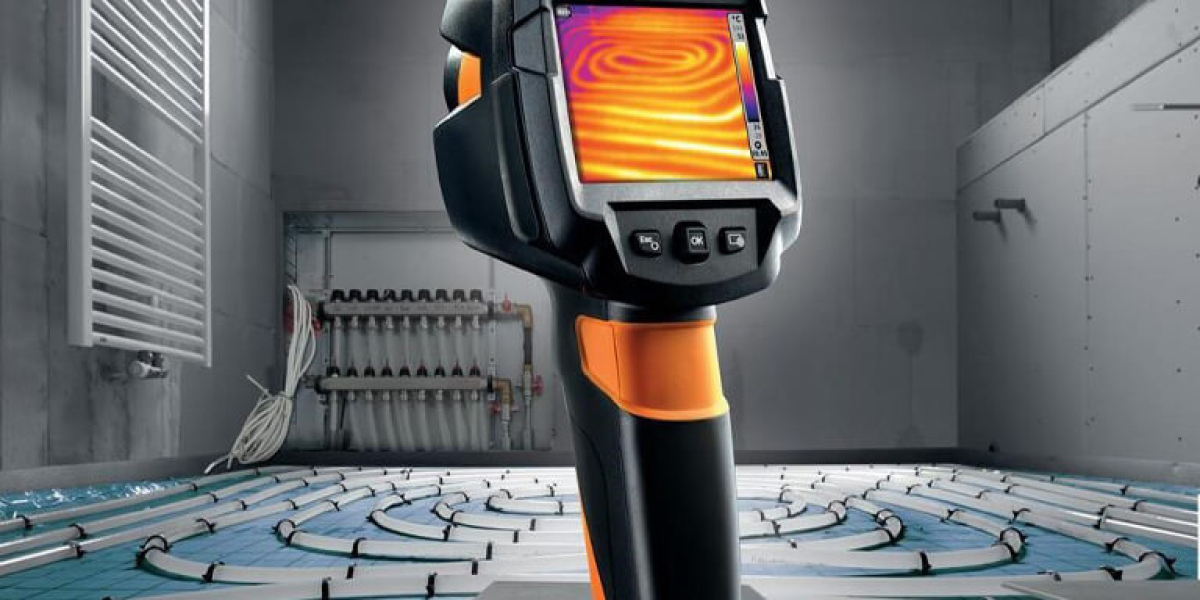

To enhance the effectiveness of visual inspection, various tools are utilized:

- Magnifying Glasses: These allow inspectors to see small defects clearly.

- Digital Cameras: High-resolution images can be captured for further analysis.

- AI-Powered Systems: Advanced algorithms can detect anomalies that may be missed by the human eye.

For instance,  showcases how technology can enhance the visual inspection process.

showcases how technology can enhance the visual inspection process.

Benefits of Visual Inspection in Quality Control

The advantages of implementing visual inspection are numerous:

- Cost-Effective: It reduces the need for extensive testing and can be performed quickly.

- Immediate Feedback: Inspectors can provide instant feedback, allowing for quick corrections.

- Versatility: It can be applied across various industries, from manufacturing to food safety.

Challenges and Considerations

While visual inspection is beneficial, it is not without challenges. Human error can lead to missed defects, and environmental factors may affect visibility. Therefore, combining visual inspection with other quality control methods can enhance overall effectiveness.

Conclusion

In summary, visual inspection is an essential component of quality control that ensures products meet safety and quality standards. By understanding the techniques, tools, and benefits associated with this method, businesses can improve their quality assurance processes. As industries continue to evolve, integrating advanced technologies into visual inspection will likely enhance its effectiveness and reliability.