Air compressors are versatile tools that play a crucial role in various industries and applications. Whether you are a DIY enthusiast or a professional, understanding the different types of air compressors and their uses can significantly enhance your efficiency and productivity.

What Are Air Compressors?

Air compressors are devices that convert power into potential energy stored in pressurized air. This process involves drawing in air and compressing it, which can then be used to power tools, inflate tires, or even operate machinery. But why are air compressors so essential? The answer lies in their ability to provide a reliable source of compressed air for a multitude of applications.

Types of Air Compressors

There are several types of air compressors, each designed for specific tasks. Understanding these types can help you choose the right one for your needs.

- Reciprocating Air Compressors: These are the most common type, using a piston to compress air. They are ideal for small to medium tasks.

- Rotary Screw Compressors: These compressors use two rotating screws to compress air. They are efficient and suitable for continuous operation.

- Scroll Compressors: Utilizing two spiral elements, scroll compressors are known for their quiet operation and energy efficiency.

- Centrifugal Compressors: These are used for large-scale applications, employing a rotating disk to compress air. They are typically found in industrial settings.

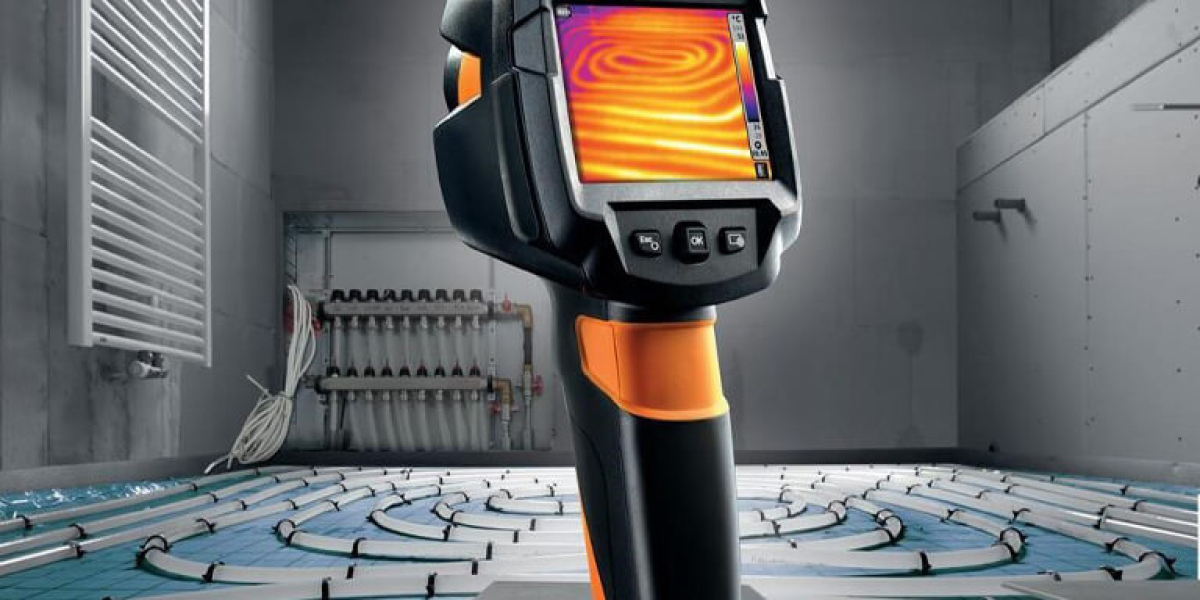

Applications of Air Compressors

Air compressors are used in a variety of applications across different sectors. Here are some common uses:

- Automotive Repair: Air compressors power pneumatic tools such as impact wrenches and spray guns.

- Construction: They are essential for operating heavy machinery and tools on construction sites.

- Manufacturing: Air compressors are used in assembly lines for powering tools and equipment.

- HVAC Systems: They play a vital role in heating, ventilation, and air conditioning systems.

Choosing the Right Air Compressor

When selecting an air compressor, consider the following factors:

- Pressure Requirements: Determine the PSI (pounds per square inch) needed for your tasks.

- Tank Size: A larger tank can store more air, allowing for longer tool operation without interruption.

- Portability: If you need to move the compressor frequently, consider a lightweight and compact model.

For more specialized applications, you may want to explore options like  , which offers a range of high-quality air compressors tailored to specific needs.

, which offers a range of high-quality air compressors tailored to specific needs.

Conclusion

In summary, understanding air compressors and their various types and applications is essential for anyone looking to enhance their work efficiency. By considering your specific needs and the features of different compressors, you can make an informed decision that will serve you well in your projects. Whether for home use or industrial applications, the right air compressor can make all the difference.